Why Choose Anodizing Over Nickel Plating for Metal Parts?

Why Choose Anodizing Over Nickel Plating for Metal Parts?

Blog Article

Metal finishing plays a crucial role in enhancing the longevity, appearance, and resistance to corrosion of metal components. Among the various metal finishing techniques, anodizing and nickel plating stand out as popular choices. Each method offers distinct advantages suited for specific applications. This article will explore the intricacies of anodizing and nickel plating, compare their merits, and discuss the common metal parts that undergo these processes. We'll also touch on anodizing color options, the equipment used in anodizing operations, the significance of surface preparation, and responsible wastewater handling.

Understanding Anodizing as a Metal Finishing Technique

Anodizing is an electrochemical procedure that amplifies the natural oxide layer on metal surfaces, predominantly aluminum. This reinforced oxide layer boosts corrosion resistance, durability, and lends a decorative finish to the metal. The process entails immersing the metal component in an electrolytic solution and applying an electric current, which induces oxidation.

Dye Colors and Equipment in Anodizing

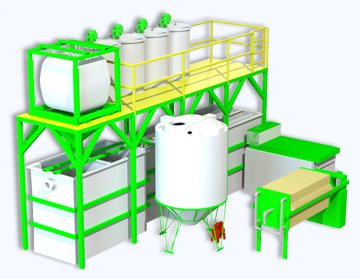

One of the appealing features of anodizing is the variety of dye colors available for achieving different aesthetic finishes. Common anodizing dye colors include black, blue, red, gold, and green, among others. The anodizing equipment for sale ranges from simple DIY kits to sophisticated industrial setups. Professional anodizing companies use specialized equipment, such as polypropylene tanks, ac to dc plating rectifiers, and controller stations, to ensure consistent and high-quality results.

Overview of Nickel Plating

Nickel plating involves depositing a nickel layer onto metal surfaces to elevate appearance, corrosion resistance, and wear durability. This plating can be achieved through electrolytic or electroless methods. While electrolytic nickel plating uses an electric current for deposition, electroless nickel plating relies on chemical reactions.

Comparing Anodizing and Nickel Plating Benefits

**Anodizing:**

- **Corrosion Resistance:** Anodized components exhibit exceptional resistance to corrosion, making them perfect for outdoor and marine use.

- **Decorative Finishes:** The diverse anodizing dye palette allows for customized and attractive finishes.

- **Durability:** The anodized layer becomes integral to the metal, ensuring a resilient and enduring finish.

**Nickel Plating:**

- **Wear Resistance:** Nickel-plated parts excel in wear resistance, suitable for mechanical components.

- **Smooth Appearance:** Nickel plating imparts a glossy and smooth finish, enhancing the metal's visual appeal.

- **Electrical Conductivity:** Nickel's high electrical conductivity makes it apt for electronic and electrical applications.

Common Metal Components Subjected to Finishing

Both anodizing and nickel plating find applications across various metal components, including:

- **Automotive:** Engine parts, trim, and wheels.

- **Aerospace:** Aircraft components, fasteners, and hydraulic fittings.

- **Consumer Goods:** Electronics, household appliances, and jewelry.

- **Industrial Machinery:** Pumps, valves, and machine parts.

The choice between anodizing and nickel plating hinges on the specific needs of the application, such as resistance to corrosion, wear, and desired aesthetics.

The Significance of Metal Surface Cleaning

Before undergoing a metal finishing process, it is crucial to clean the metal surfaces thoroughly to remove any contaminants, oils, or residues. Proper cleaning ensures better adhesion of the anodizing or nickel plating layer, resulting in a more durable and high-quality finish. Use of a paint stripper for metal or specialized cleaning solutions can effectively remove stubborn contaminants and prepare the metal surface for the finishing process.

Responsible Wastewater Management

Wastewater generated during the anodizing and nickel plating processes contains various chemicals and metals, which can be harmful to the environment if not properly treated and disposed of. Conducting a jar test for wastewater helps in determining the appropriate treatment method to remove contaminants and ensure compliance with environmental regulations. Proper wastewater management is essential to minimize environmental impact and maintain sustainability in metal finishing operations.

Join A Brite Company as an Independent Sales Representative

If you are looking to become an independent sales rep for A Brite Company, a renowned supplier of metal finishing equipment and supplies, now is an opportune moment! A Brite Company offers an extensive range of anodizing equipment, including tanks, rectifiers, controllers, and supplies, as well as nickel plating solutions and equipment. Renowned for quality and innovation,With a reputation for quality and innovation, the A Brite Company is committed to providing the best plating equipment manufacturers can buy to meet the diverse needs of the metal finishing industry.

In conclusion, both anodizing and nickel plating are effective metal finishing techniques, each with its unique advantages suited for specific applications. The selection between these methods depends on the application's specific needs, such as corrosion and wear resistance, along with aesthetic preferences. Proper surface cleaning before metal finishing and responsible wastewater management are pivotal for quality and sustainability in metal finishing processes.

A Brite Company, a leading supplier of metal finishing equipment and supplies, is expanding its sales network. If you're interested in joining A Brite Company as an independent sales representative, we invite you to explore opportunities on their careers page.

Report this page